|

| A finished Lancaster is ready to be rolled out from Block 'A' |

Nuffield: 1936–1940

In 1936, the British government had formalized a plan under

the Air Ministry called the Shadow factory plan to increase capacity within

Britain's aircraft industry. Headed up by automotive pioneer Herbert Austin,

the plan was to create nine new factories and add additional capacity and

facilities to Britain's existing car manufacturing plants to enable them to

quickly turn to aircraft production should the political situation in Europe

change towards war.

In 1936, the Air Ministry purchased a parcel of land

opposite Castle Bromwich Aerodrome which encompassed an old sewage works.

Developed and managed by the Nuffield Organization, owners of Morris Motors,

they were briefed to manufacture Supermarine Spitfire fighters and later Avro

Lancaster bombers. The theory was that the local Birmingham skills-base and production

techniques used in the manufacture of motor vehicles could be transferred to

aircraft production.

CBAF ordered the most modern machine tools then available

which were being installed two months after work started on the site. Although

Morris Motors under Lord Nuffield (an expert in mass motor-vehicle

construction) managed and equipped the factory, it was funded by government

money. When the project was first mooted, it was estimated that the factory

would be built for £2,000,000, however, by the beginning of 1939, this cost had

doubled to over £4,000,000. The Spitfire's stressed-skin construction required

precision engineering skills and techniques outside the experience of the local

labor force which took some time to train. Aircraft and sub-assemblies were

taken across the Chester Road to Castle Bromwich Aerodrome; though early plans

included an aerial bridge from E block to the airfield. Very large hangar-like

buildings were erected on the east side of the airfield, which were originally

referred to as 'Erecting Sheds', where aircraft were prepared for flight

testing. They were for the most part referred to by personnel as the 'Flight

Sheds'.

CBAF's chief test pilot was Alex Henshaw MBE who managed a

team of pilots who had the job of flight-testing the aircraft. The Air

Transport Auxiliary were responsible for dispersing tested machines to the

Maintenance Units around the country for the fitting of radio-telephones and

other equipment. As any build-up of machines on the airfield would be vulnerable

to aerial attack, testing was carried out during daylight in almost any

weather.

CBAF produced all versions of the Spitfire from the Mk II

onwards. This aircraft had the more powerful Rolls-Royce Merlin XII engine,

providing 1,150 horsepower (860 kW), an increase of 120 horsepower (89 kW) over

the Mk I, and could be used with either the de Havilland or Rotol propellers.

The first Mk II flew on 24 September 1939.

However, even as the first Spitfires were being built in

June 1940, the factory was still incomplete and there were numerous problems

with the factory management which ignored tooling and drawings provided by

Supermarine in favor of tools and drawings of its own designs. Meanwhile, the

workforce, while not completely stopping production, continually threatened

strikes or "slow downs" until their demands for higher than average

pay rates were met. By May 1940, Castle Bromwich had not yet built its first

Spitfire in spite of promises that the factory would be producing 60 per week starting

in April.

Key players, such as Alex Henshaw, viewed the problems as

primarily those of poor management during the initial phase. Workers worked

twelve-hour on and twelve-hours off until bombings forced a switch to a

three-shift, eight-hour system. Henshaw attended the diamond jubilee in 1996 of

the founding of the CBAF, hosted by Jaguar Cars Limited in the old factory and

remained fulsome in his praise for the workforce until his death.

Vickers-Armstrong: 1940–1945

After the fall of the government of Neville Chamberlain, new

Prime Minister Winston Churchill appointed press tycoon Lord Beaverbrook as the

Minister of Aircraft Production. On 17 May, Beaverbrook telephoned Nuffield and

maneuvered him into handing over control of the Castle Bromwich plant to

Beaverbook's Ministry. Nuffield was furious and reported the incident to

Churchill, but Beaverbrook countered by sending in aircraft expert Sir Richard

Fairey who wrote a secret report which detailed how expensive machinery had

been unused, the assembly line in chaos, and the employees not doing their

work:

Labour

is in a very bad state. Discipline is lacking. Men are leaving before time and

coming in late, taking evenings off when they think fit. In parts of the

factory I noticed that the men did not even stir themselves at the approach of

the Works Manager. The labour in the Midlands is not “playing the game”. They

are getting extra money and are not working in proportion for it.

Beaverbrook, who had disturbed the Air Ministry by agreeing

with the vision of Air Vice Marshal Hugh Dowding that Britain at that time

needed defensive fighters over attacking bombers, immediately cancelled all

Castle Bromwich contracted bombers, which at that point included the

Handley-Page Halifax and the Vickers Wellington. He then sent in experienced

management staff and workers from Supermarine, and gave over control of the

factory to Vickers-Armstrong (Supermarine's parent company). Although it would

take some time to resolve the problems, CBAF achieved full production in June

1940, when 10 Spitfire Mk IIs were built; 23 in July; 37 in August; and 56 in

September. No. 611 Squadron at RAF Digby the first squadron to receive the Mk

II in August 1940, notably late in the Battle of Britain.

The wisdom of the shadow factory scheme was demonstrated in

September 1940, when the Supermarine factory in Southampton was bombed, and

production there temporarily stopped. CBAF went on to become the largest and

most successful plant of its type during the 1939–45 conflict. As the largest

Spitfire factory in the UK, by producing a maximum of 320 aircraft per month,

it built over half of the approximately 20,000 aircraft of this type. By the

time production ended at Castle Bromwich in June 1945, a total of 12,129 Spitfires

(921 Mk IIs, 4,489 Mk Vs, 5,665 Mk IXs, and 1,054 Mk XVIs) had been built.

Subsequently receiving an order for 200 production aircraft,

the first CBAF Lancaster was flown on 22 October 1943 by Alex Henshaw. Given

the airframe number HK535 and fitted with Merlin 22 engines, it was issued to

No. 463 Squadron Royal Australian Air Force. It was lost on a raid over Lille,

France, during the night of 10/11 May 1944. Production of Lancasters reached a

peak of 25 in December 1944, a record for the quantity produced anywhere.

The film Jane Brown Changes Her Job (1941) was made in the

factory, and scenes for the 1943 film Millions Like Us were shot there, with

employees serving as extras.

Some original wartime features can still be seen such today,

such as the faded remains of green camouflage paint. This can still be seen on

the top of some older production buildings, such as F Block, that is now used

as trim and final assembly for the Jaguar XJ. Close inspection will also reveal

that all the cast-iron hoppers of the factory's rainware have a winged-roundel

motif cast into them. At the Jubilee celebrations in 1997, a plaque was

unveiled by Alex Henshaw just inside the old wartime main gates to the factory

site. At the moment of unveiling, ex-Red Arrows founder Ray Hanna made a single

pass over the ceremony in a Spitfire MkIX, MH434. This aircraft was not only

built at the CBAF, but was test-flown by Henshaw himself. The aircraft had been

specially named for the occasion by Henshaw at Elmdon Airfield (now called

Birmingham International Airport). After the unveiling, both Henshaw and Hanna

attended a celebratory luncheon with many local dignitaries and many former

CBAF employees. The whole event was supported and funded by Jaguar Cars Ltd.

|

| Castle Bromwich - B Block construction June 1939. |

|

| Winston Churchill chats with Alex Henshaw at Castle Bromwich. |

|

| Bomb damage to D Block after raid - August 1940. |

|

| Production of Lancaster nose sections in Block A. |

|

| Supermarine Spitfire Mk IIA (Royal Air Force code P7350) at Kemble Air Day, Kemble Airport, Gloucestershire, England. Owned by the UK Battle of Britain Memorial Flight. Quote from the BBMF website: P7350 is the oldest airworthy Spitfire in the world and the only Spitfire still flying today to have actually fought in the Battle of Britain. She is believed to be the 14th aircraft of 11,989 built at the Castle Bromwich ‘shadow' factory, Birmingham. Entering service in the August of 1940, she flew in the Battle of Britain serving with 266 Squadron and 603 (City of Edinburgh ) AuxAF Squadron. (Adrian Pingstone) |

|

| Castle Bromwich Aircraft Factory, heavily camouflaged. |

|

| The Prime Minister Winston Churchill observes a female riveter working on a Supermarine Spitfire at the Castle Bromwich factory in Birmingham, England, on 28 September 1941. (Imperial War Museum H14259) |

.jpg) |

| The flight line at Castle Bromwich in 1944 with massed Spitfire IXs and two Lancasters. |

.jpg) |

| Tropical filter-fitted Spitfire V ER810 at Castle Bromwich in October 1942. It carries the name ‘Inca’ on the forward fuselage, funded by the people of Lima, Peru |

.jpg) |

| Final assembly, C Block Castle Bromwich Aircraft Factory, circa 1943. (Birmingham Museums Trust) |

.jpg) |

| Spitfire F.22s on the line in late 1945. Many of these were completed and flight tested at Keevil or South Marston as Castle Bromwich production wound down. In the middle on the left is PK581, which was issued to the RAF in October 1945. |

.jpg) |

| Women workers preparing Spitfire parts for spraying. (Birmingham Museums Trust) |

.jpg) |

| Main drawing office, Castle Bromwich Aircraft Factory, c.1943. (Birmingham Museums Trust) |

|

| Prime Minister Winston Churchill talking to Alex Henshaw, after a 1941 demonstration flight on a Spitfire. (Imperial War Museum H14264) |

|

| The Sentinel monument on Spitfire Island, Castle Bromwich, Birmingham commemorates the manufacture of almost 12,000 Spitfire fighter aircraft by Vickers Armstrong at this site between 1940 and 1945. The sculpture was designed by Tim Tolkien, great nephew of J R R Tolkien author of The Lord of the Rings and was unveiled in October 2000 by Alex Henshaw the former chief test pilot at Castle Bromwich aerodrome. |

|

| Drying a Spitfire wing leading edge after painting with a barrage of infrared lights. |

|

| Women hand-sewing Spitfire rudders at the Castle Bromwich Aircraft Factory. |

|

| The pattern makers’ shop; working on items for Lancasters as well as Spitfires. |

|

The main works canteen.

|

|

| Fuselage jigs in the foreground with completed and painted fuselages behind. |

|

| Castle Bromwich test pilots, left to right: Flt Lt J Rosser, Alex Henshaw, Norwegian Captain Olav Ullstad and Czechoslovakian Flt Lt Venda Jicha. |

|

| The flight sheds, looking east. |

|

| Birmingham was blitzed by the Luftwaffe several times from 1940 through to 1943, with horrific loss of life and property. The Castle Bromwich Aircraft Factory (CBAF) was on the receiving end on the night of August 13/14, 1940, just a fraction of the damage is illustrated. Seven people perished in the raid and another 41 were badly injured, but production was hardly interrupted. |

|

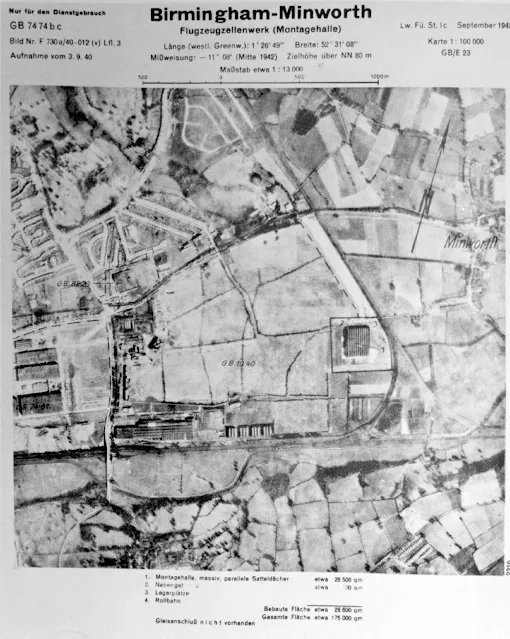

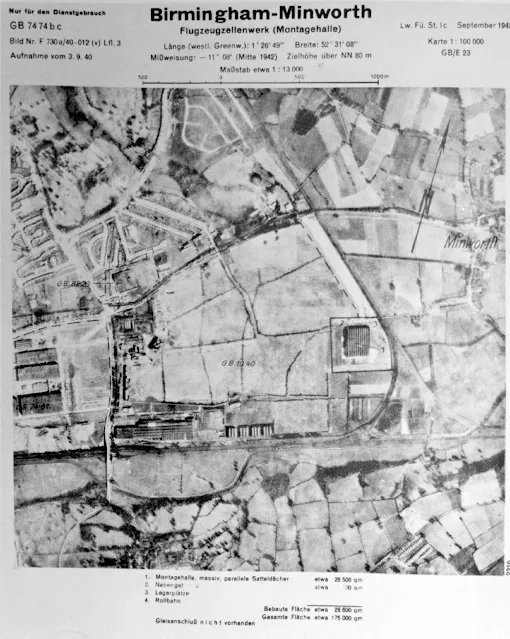

| A Luftwaffe target chart (above), dated September 3, 1940 was probably taken for post-raid damage assessment and it was updated in September 1942. Clear on the chart is the railway line running from the northwest, with one section taking a sharp curve to the east, in the direction of central Birmingham. This acted as the eastern and southern boundary of the airfield and factory site. Wending its way across the middle of the target, and forming the northern boundary, is the Birmingham and Fazeley Canal. On the extreme lower left is part of the huge CBAF site and to the right of that the British Industries Fair building. |

|

| Castle Bromwich: The grass field site prior to the start of construction 1937. |

|

| Main gate entrance, Castle Bromwich Aircraft Factory. |

|

| Spitfire assembly, Castle Bromwich Aircraft Factory. |

|

| Women on the Spitfire production line. |

|

| Aircraft at the Castle Bromwich plant. |

|

| Spitfires come off the production line. |

|

Spitfire Production at Castle Bromwich, 1940. Painting by Roy Garner. Jaguar Daimler Heritage Trust

|

|

| Spitfire Production: A general view of the factory floor where Spitfire fuselages are under construction at an aircraft factory in the Midlands. (Imperial War Museum HU89805) |

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)