|

| US Army 81-mm mortar crew in North Africa, 1943. |

The M1 mortar is an American 81 millimeter caliber mortar. It was based on the French Brandt mortar. The M1 mortar was used from before World War II until the 1950s when it was replaced by the lighter and longer ranged M29 mortar.

General Data

Type: Infantry mortar

Place of origin: United States

In service: 1935–1952

Used by:

United States

Vietnam

Other users

Wars:

World War II

Korean War

Algerian War

Vietnam War

Nicaraguan Revolution

Salvadoran Civil War

Weight:

Tube 44.5 lb (20 kg)

Mount 46.5 lb (21 kg)

Base plate 45 lb (20 kg)

Total 136 pounds (62 kg)

Length: 3 ft 11 in (1.19 m)

Crew: 8 (squad leader, gunner, assistant gunner, 5 ammunition bearers)

Caliber: 81 mm (3.2 in)

Rate of fire:

18 rpm sustained

30-35 rpm maximum

Muzzle velocity: 700 ft/s (210 m/s)

Maximum firing range: 3,300 yd (3,000 m)

Sights: M4

Ammunition

M43A1 light HE: 7.05 lb (3.20 kg); HE filling 1.22 lb (0.55 kg); range min 100 yd (91 m); range max 3300 yd (zone 7, 3018 m); 80% frag radius 25 yd (23 m) (compared favorably with the 75 mm howitzer). M52 superquick fuze (explode on surface).

M43A1 light training: an empty version of the M43A1 light HE with an inert fuze. It was used as a training shell until it was replaced by the M68 training practice shell.

M45 heavy HE: 15.10 lb (6.85 kg); HE filling 4.48 lb (2.03 kg); range max 1275 yd (zone 5, 1166 m); bursting radius comparable to the 105 mm howitzer. Equipped with M45 (super quick/delay action selective) or M53 (delay action only) P.D. fuze.

M56 heavy HE: 10.77 lb (4.86 kg); HE filling 4.31 lb (1.96 kg); range max 2655 yd (zone 5, 2428 m), standard for issue and manufacture shell replacing M45. It used the M53 fuze back in 1944, but it was at some point replaced by the M77 Timed Super Quick (TSQ) fuze.

M57 WP (white phosphorus) "bursting smoke": 10.74 lb (4.87 kg); range max 2470 yd (2260 m); designed to lay down screening smoke, but had definite anti-personnel and incendiary applications.

M57 FS (a solution of sulfur trioxide in chlorosulfonic acid) chemical smoke: 10.74 lb (4.87 kg), range max 2470 yd (2260 m); laid down dense white fog consisting of small droplets of hydrochloric and sulfuric acids. In moderate concentrations, it is highly irritating to the eyes, nose, and skin.

M68 training practice: 9.50 lb to 10.10 lb. An inert teardrop-shaped cast iron shell without provision for a fuze well that was used to simulate the M43 light HE shell. The casing on early models was painted black but post-World War 2 versions are painted blue. It came in 9 different weights (engraved on the shell) to allow it to simulate shell firing with and without booster charges. Weight zone one (9.5 lbs.) simulated a shell with the maximum of 8 booster charges and weight zone nine (10.10 lbs.) simulated the shell being fired without booster charges.

M301 illuminating shell: range max 2200 yd (2012 m); attached to parachute; burned brightly (275,000 candelas) for about 60 seconds, illuminating an area of about 150 yards (137 m) diameter. It used the M84 time fuze, which was adjustable from 5 to 25 seconds before priming charge detonated, releasing the illuminator and chute.

Fuzes

The M1 mortar's shells sometimes used the same fuzes as the shells for the M2 60 mm mortar. An adapter collar was added to the smaller fuzes to allow them to fit the larger shells.

M43 mechanical timing (MT) fuze: clockwork timed delay fuze. Models M43A5.

M45 point detonating (PD) fuze: selective fuze that could be set for time delay or super-quick (less than a second) detonation on impact. Replaced by the M52 and M53 fuzes.

M48 point detonating (PD) fuze: selective powder train burning fuze that can be set to super quick or delay ignition on impact. The factory pre-set delay time was stamped on the shell body. If the super-quick flash ignition failed, the delay fuse kicked in. If set on delay, the super-quick flash igniter mechanism was immobilized to prevent premature ignition. Models: M48, M48A1, M48A2 (either 0.05 or 0.15 second Delay), & M48A3 (0.05 second delay).

M51 point detonating (PD) fuze: selective powder train burning fuze that can be set to super quick or delay ignition after impact. It is a modification of the M48 fuze with the addition of a booster charge. Models: M51A4, M51A5 (M48A3 Fuze with M21A4 booster).

M52 point detonating super-quick (PDSQ) fuze: super-quick fuze that activates less than a second after impact. The pre-war M52 was made of aluminum, the M52B1 model was made of Bakelite, and the M52B2 model had a Bakelite body and an aluminum head; the suffix would be added to the shell designation.

M53 point detonating delay (PDD) fuze: delay fuze that activates after impact.

M54 time and super-quick (TSQ) fuze: powder train burning fuze that can be set for time delay (slow burn) or super-quick (flash ignition) detonation on impact.

M77 time and super quick (TSQ) fuze: powder train burning fuze that can be set for time delay (slow burn) or super-quick (flash ignition) detonation on impact.

M78 concrete penetrating (CP) fuze: delay fuze that was set off after the shell had impacted and buried itself to increase the damage done.

M84 mechanical timing (MT) fuze: clockwork fuze that can be set from 0 to 25 seconds in 1-second intervals; seconds were indicated by vertical lines and 5-second intervals were indicated by metal bosses to allow it to be set in low-light or night-time conditions.

M84A1 mechanical timing (MT) fuze: clockwork fuze that can be set from 0 to 50 seconds in 2-second intervals.

Users

It may be found in nearly all the non-Communist countries, including:

Austria: used on M21 mortar motor carriage

Belgium: made under license

Republic of China

Colombia

Dominican Republic

El Salvador

Ethiopia

France

Greece

Guatemala

Haiti

Honduras

Japan

Laos

Libya

Mexico

Myanmar: M-43

South Korea: The Armed Forces was equipped with 386 M1s before the Korean War, and 822 were in service with the Army by the end of the war. Began replacing with M29A1 or KM29A1 in 1970s.

Turkey

Thailand

United States

Uruguay

South Vietnam

North Vietnam

Vietnam

|

| US Army 81mm mortar crew in jungle. Position of mortar tube almost vertical indicates enemy is very close. |

|

| Members of the 504th Parachute Infantry Regiment prepare to fire an 81mm mortar during the battle for Italy. |

|

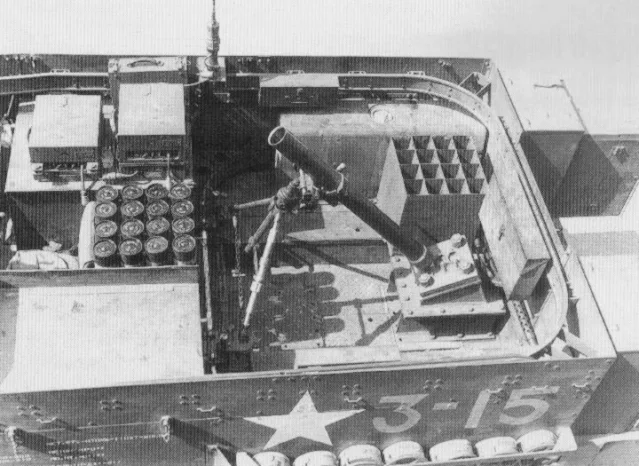

| 81mm Mortar Carrier M4 of 41st Armored Infantry, 2nd Armored Division, in April 1944. The vehicle was modified so that the mortar will fire in forward direction. April 1, 1944. |

|

| 81mm mortar crew in action at Camp Carson, Colorado. April 24, 1943. |

|

| U.S. First Army soldier manning an M1 81mm mortar listens for fire direction on a field phone during the German Ardennes offensive. January 19, 1945. |

|

| M4 Mortar Carrier. March 25, 1942. |

|

| 81mm mortars support Patton's drive on Palermo. |

|

| L-R: Pvt. Hubert Reiner, Pfc. Charles Strong and Cpl. Ken Shane. November 12, 1942. Tynan, Northern Ireland. 1st Battalion, 133rd Infantry Regiment, 34th Infantry Division. |

|

| Men fire smoke shells from an 81mm mortar supporting infantrymen of the U.S. First Army as they advance on a pillbox. 424th Infantry Regiment, 106th Infantry Division. February 28, 1945. |

|

| Pvt. Ray E. Thiel of 3rd Bn., Mortar Platoon, 504th Parachute Infantry Regiment, 82nd Airborne Division, cleans 81mm mortar. Cisterna area, Italy. March 8, 1944. |

|

| Firing a mission with 81mm mortar, L to R, Pvt. Ernest Dolloff and Cpl. John F. Richards, Company D, 141st Infantry Regiment, 36th Infantry Division. Haguenau Area, France. March 9, 1945. |

|

| Mortar crew sheltered behind the Maginot Line pillbox near Lembach, prepares to fire 81mm shells at enemy. 3rd Battalion, 157th Infantry Regiment, 45th Infantry Division. December 13, 1944. |

|

| Infantrymen fire 81mm mortar over house in Wingen. 180th Infantry Regiment, 45th Infantry Division. December 15, 1944. |

|

| Men of the Mortar Platoon, 126th Inf. Regt., 32nd Div., are shown firing the 81mm mortar on the Japanese positions in the Orboredo River sector, Luzon, P.I. February 25, 1945. |

|

| Heavy 81mm mortar firing into Japanese positions across the Tsinamutu River, near Kuraio Mission, Bougainville. February 24, 1944. |

|

| M21 81mm Mortar Carrier at tests. April 28, 1944. |